At the heart of any successful quality management system is certified leadership. In the field of industrial services—especially coating, insulation, fabrication, and construction—QA/QC (Quality Assurance and Quality Control) Managers play a vital role in ensuring that all works meet international quality standards. Their certifications are not just credentials—they are a testament to their technical expertise, commitment to excellence, and ability to lead high-stakes quality programs in complex environments.

Key Certifications Held by QA/QC Managers

1. NACE Coating Inspector Certification Program (CIP)

- Issued by: AMPP (Association for Materials Protection and Performance, formerly NACE and SSPC)

- Levels: CIP Level 1, Level 2, and Level 3

- Scope: This globally recognized certification focuses on coating inspection and corrosion control for industries such as oil & gas, marine, and infrastructure.

- Why It Matters: It equips QA/QC Managers with the skills to inspect surface preparation, monitor coating application, assess coating performance, and write technical reports based on NACE/SSPC standards.

2. ISO 9001:2015 Lead Auditor

- Issued by: Accredited training bodies (e.g., IRCA, Exemplar Global)

- Scope: Provides in-depth knowledge on auditing quality management systems and ensuring compliance with ISO 9001:2015.

- Why It Matters: This certification empowers QA/QC Managers to lead internal and external audits, identify gaps, and drive continual improvement across departments.

3. ASNT Level II/III (Non-Destructive Testing)

- Issued by: American Society for Nondestructive Testing

- Scope: Covers NDT techniques like Ultrasonic Testing (UT), Magnetic Particle Testing (MT), Dye Penetrant Testing (PT), and Radiographic Testing (RT).

- Why It Matters: For projects involving structural integrity and weld inspection, QA/QC Managers with ASNT certification ensure that critical flaws are identified before they become costly failures.

4. AWS-CWI (Certified Welding Inspector)

- Issued by: American Welding Society

- Scope: Comprehensive qualification covering welding codes, procedures, and inspection standards.

- Why It Matters: Ensures that welds meet industry codes (e.g., ASME, API, AWS) and project-specific requirements.

5. NEBOSH / IOSH Certifications

- Focused on: Health, Safety, and Environmental standards in the workplace

- Why It Matters: Though not strictly quality-related, QA/QC Managers often work closely with HSE teams. These certifications enhance their awareness of safety protocols, helping ensure safe and compliant quality operations.

The Role of Certified QA/QC Managers in Project Delivery

Certified QA/QC Managers go beyond checking boxes. Their responsibilities include:

- Developing and implementing Quality Control Plans (QCPs)

- Conducting in-process inspections and final acceptance checks

- Coordinating with clients, third-party inspectors, and internal teams

- Leading root cause analysis and corrective action processes

- Providing training and mentorship to inspection staff and technicians

- Maintaining full documentation and traceability

Their leadership ensures that materials, workmanship, and processes adhere strictly to both client requirements and international norms—such as ISO, NACE, SSPC, NORSOK, and British Standards.

Why Certified Leadership Matters

In industries where precision, durability, and safety are non-negotiable, certified leadership is a critical investment. It builds trust with clients, reduces the risk of rework, and ensures that quality is not just controlled—but embedded in every layer of the project.

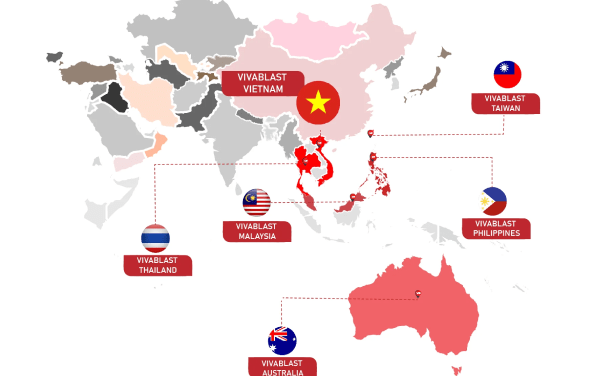

VIVABLAST’s Commitment to Professional Development

At VIVABLAST, we not only deliver high-quality QA/QC services but also support the professional growth of industry personnel. Through collaboration with AMPP (formerly NACE/SSPC), VIVABLAST facilitates the delivery of internationally recognized Coating Inspector Certification programs in Vietnam, combining theoretical knowledge with hands-on practice. This creates valuable opportunities for participants to strengthen their quality control expertise and meet the rigorous demands of global industrial projects.

>> LEARN MORE