When it comes to passive fire protection, it would be a huge omission if we don’t mention intumescent coatings. So what is the intumescent coating, and what types are there? Let’s learn more with us in the following article.

The application of intumescent coating technology in passive fire protection effort

This article contains three main sections:

- The definition of passive protection and intumescent coating

- Three general types of intumescent coating

- The intumescent coating solution provided by VIVABLAST

1. What are passive fire protection and intumescent coating? What are the applications of this coating?

First of all, before diving into the intumescent coating information, we will glance at the definition of the passive protection method. Passive fire protection (PFP) is the preparedness to reduce the impact of a fire on the safety of people and infrastructure. The main effect of PFP solutions is to prevent fire spread, providing more time for rescuing people. An intumescent coating is a protective layer that works on the basis of a thermal reaction, resulting in thermal expansion and the formation of an insulating layer on the surface, which can release water, as the case may be. This is considered a cost-effective option and has good fire and corrosion resistance, especially for structures made of alloys and steel. Since they are mainly in the form of paint, these coatings are also used for decoration.Intumescent paint can be considered the lightest passive fire protection material. Intumescent paint is usually applied with a spray gun to ensure speed and quality. For small-scale projects, we can use paint brushes instead of sprayers. Painting time usually lasts about 120 minutes, depending on the case.

An intumescent coating is a protective layer that works on the basis of a thermal reaction, resulting in thermal expansion and the formation of an insulating layer on the surface, which can release water, as the case may be. This is considered a cost-effective option and has good fire and corrosion resistance, especially for structures made of alloys and steel. Since they are mainly in the form of paint, these coatings are also used for decoration.Intumescent paint can be considered the lightest passive fire protection material. Intumescent paint is usually applied with a spray gun to ensure speed and quality. For small-scale projects, we can use paint brushes instead of sprayers. Painting time usually lasts about 120 minutes, depending on the case.

2. Passive fire protection method: 3 main types of intumescent coating

Intumescent coating technology can be classified into 3 general types: Water-based, Solvent-based and Epoxy-based Intumescent. Let’s take a look at the comparison chart below:

| Water-based | Solvent-based | Epoxy-based | |

| Definition | Paints use water instead of oil to create the pigment and binder of the paint. The pungent smell of paint is the only indication that this is oil paint and not water paint. | So-called “Oil-based” or “Alkyd” paints, solvent-based paints are made with alkyd (synthetic) or linseed (natural oils). They contain more organic compounds than water-based ones. | Paints that are made from acrylic rubber resin with a small amount of epoxy. |

| Advantages |

|

|

|

| Disadvantages |

|

|

|

| Applicable environment | C1 and C2 environments only;Indoor structures. | C1-C3 environments only;Semi-exposed areas in a building (with topcoat) | Can be applied in the harshest environments such as petrochemicals. |

In general, water-based and oil-based paints are only suitable for indoor works; oil-based paints apply to semi-exposed areas. And epoxy paint can be used not only outdoors but also in harsh industrial conditions. Based on the information, you can choose the suitable paint for your passive fire protection plan.

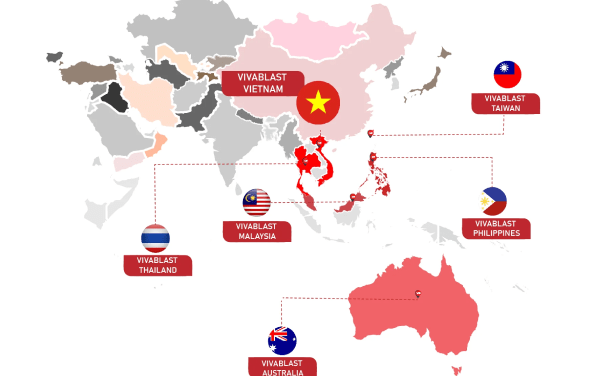

3. The introduction about the passive fire protection solutions at VIVABLAST

VIVABLAST is one of the leading passive fire protection solutions providers Vietnam and other Southeast Asia countries. Intumescent is one of four PFP solutions included in our current portfolio.Regarding intumescent coating, we master all types of water and solvent-based intumescent applications. Our solutions are used to protect commercial and public buildings, oil and gas infrastructures, and plants, onshore and offshore structures. We are also a specialist in applying multiple types of intumescent coatings, such as Chartek, Interchar, Firefox, Nullifire, and Pitt Char.Our passive fire protection system can be helpful for:

- Industrial factories (onshore and offshore);

- Buildings and factories;

- Hospitals, schools, and gymnasiums infrastructure.

If you want to strengthen the fireproofing barrier for your structures by using one more PFP method besides intumescent coating, VIVABLAST suggests three choices below:

- Boarding / sealing systems: Used for penetration seals, cables, and other utilities.

- Ablative spray: Specially designed to protect grouped or bundled electrical cables and penetration seals.

- Fireproofing epoxy paint and Cementitious sprays: Designed for the direct protection of structural steelwork.

VIVABLAST is an experienced expert in consulting, supplying, and installing PFP that can meet all your needs and requirements, from civil works of various dimensions to industrial and offshore areas. Recapping, the intumescent coating is an ideal passive fire protection choice for your safety plan. You can choose between water-based, oil-based, or epoxy-based intumescent paint based on the different situations and environmental conditions. And among numerous names of providers, VIVABLAST stands out as a leading company in PFP solutions, thanks to state-of-the-art technologies and a skillful construction team. We always give advice and construction plans based on the customer’s requirements, project characteristics, and budget, ensuring optimal efficiency.For more information, please contact VIVABLAST via:

Recapping, the intumescent coating is an ideal passive fire protection choice for your safety plan. You can choose between water-based, oil-based, or epoxy-based intumescent paint based on the different situations and environmental conditions. And among numerous names of providers, VIVABLAST stands out as a leading company in PFP solutions, thanks to state-of-the-art technologies and a skillful construction team. We always give advice and construction plans based on the customer’s requirements, project characteristics, and budget, ensuring optimal efficiency.For more information, please contact VIVABLAST via:

- Phone: (+ 84-28) 38 965 006/7/8

- Fax: (+ 84-28) 38 965 004

- Email: vivablast@vivablast.com