The composite metal coating is the modern material compensation used in many different types of construction worldwide. So what is this metal coating solution, and what special features are used so much? We will find the answer together in the following content.

1. General information of composite metal coating – Structure and properties of this solution

The main effect of the metal coating is to help the corroded machinery, equipment, and structures to return to their original state to compensate for the lost metal layer. In fact, the composite material has more outstanding anti-corrosion properties than previous traditional methods, making them the most used type of coating material today.

1.1 The meaning of composite metal coating in modern industrial applications

In this solution, the metal coating is a composite material composed of two or more different chemical or physical components. Despite its long roots, composites’ science evolved in the 1950s when rocket technology appeared in the United States. Since then, the composite technology industry has developed and spread worldwide with the common name of composite materials. This material has superior properties and uses compared to traditional methods such as metal coating or zinc coating. One of the most popular composite materials today is concrete.

1.2 The composite metal coating’s special structure

The main components of composite metal compensating material usually have two main parts are reinforcement material and base material:

- Reinforced material (also known as supporting material): This is a component with physical and mechanical properties that increases the strength and stiffness of the material. Basically, there are two types of reinforcement, fibrous and granular. The fiber form (short and long) is glass fiber or carbon fiber, … and the grain form is metal particles, clay particles, stone powder, and wood powder, …

- Base material: The base material functions as a binder, ensuring that the core components in the composite material are tightly bonded together and form a solid, uniform block. The material of the base material can be a polymer such as polyester, PE, PVC, PP, epoxy, rubber,…or molten metal, ceramic,…

1.3 Composite metal coating compensators’ outstanding properties

These outstanding features make this metal coating more and more popular in many live projects modern architectures.The outstanding features of the reinforcement material:

- The role is the point subjected to concentrated stress

- Chemical resistance in environment and temperature

- Disperses well into the background

- Facilitates processing, heat transfer, and cooling

- Environmental friendliness.

Some base material properties:

- Acts as a binder and creates a dispersion medium for the reinforcement

- Has the function of transferring stress to the reinforcement material when it encounters an external force

- Protect reinforcement material from damage due to attack by external factors

- Increased toughness of composite materials against the spread of cracks

2. Advantages and disadvantages of composite metal coating – Is this the best material?

Thanks to the outstanding features of each component, the composite metal coating has many amazing advantages, such as:

- Lightweight

- High mechanical strength, stiffness, good tensile strength

- Withstands extreme weather such as UV rays

- Good thermal and electrical insulation

- It may be chemical and abrasion-resistant

- Composite metal coating can resist corrosion, so there is no need to use more layers such as galvanized paint

- No cost in maintenance

- Easy to shape and color, convenient to change and repair

- Investment costs in production equipment, as well as maintenance costs, are not too high

- Long service life (2-3 times more durable than wood and metal)

Learn more about What’s The Difference Between Cold Galvanizing And Hot Galvanizing?

Although there are many outstanding advantages, the composite metal coating still has certain limitations. You should also learn about this for proper application. Here are some disadvantages of composites:

Although there are many outstanding advantages, the composite metal coating still has certain limitations. You should also learn about this for proper application. Here are some disadvantages of composites:

- It cannot be recycled or reused

- Raw materials are quite expensive

- It takes a long time to process

- The quality of the materials depends on the workmanship of the workers

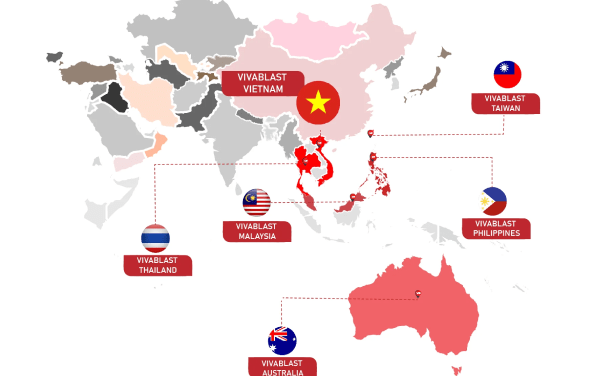

To overcome composite’s disadvantages, experts have launched a method to protect metal with Belzona coating. This method can be used as a metal compensator, protecting machines and equipment and ensuring they are resistant to environmental influences and chemical attacks. Belzona Vietnam products provide safe, easy to apply, and effective repair solutions. It is suitable for applications such as coating chemically corroded metal surfaces, replacing metal loss areas, and restoring the wings and cover of the pump.If you are confused about choosing a suitable metal coating, please contact VIVABLAST through the following information; we will advise and offer the best solution for your project:

- Phone: (+ 84-28) 38 965 006/7/8

- Fax: (+ 84-28) 38 965 004

- Email: vivablast@vivablast.com