The pipes are critical components of the plant’s boiler system. However, what solution can make the boiler system reliable and long-lasting? The answer is you will find a proven boiler tube coating product to solve it. Boiler tube coating ensures that wherever lagging, corrosion, abrasion, chemical attack, slagging, and thermal wear are problems. On the other hand, at one-tenth the cost and time of weld overlay coatings or metal applied thermal spray, boiler tube repair delivers excellent value and performance for your system.

Why is Boiler Tube Coating critical? The most popular coating materials

Boiler Tube Coating is attracting more and more interest from owners, not only bringing economic benefits but boiler tube coating is also designed to watch over process equipment exposed to high-temperature environments or systems. Coatings are constantly being enhanced in materials and coating techniques to fulfil market demands. Before learning about boiler tube insulation materials, let’s look at the advantages of pipe insulation to understand better why it is so vital.

1. The Benefits of Boiler Tube Coating – The reason why boiler coating is so important

Boiler Tube Coating is a single-component water-based technology that is applied and suitable for application temperatures up to 2000 F (1100 C). Moreover, Boiler Tube Coating material is a terrific approach to avoiding these issues and getting many other benefits.

- Superior adhesion: With the high adhesion and superior coating, Boiler Tube Coating enhanced by the unique micro-roughness of the protective coatings, can help resist the extreme physical, chemical and thermal conditions within a high-temperature environment

- Improved inspection: Boiler Tube Coating is also used as a wear indicator, which means, whereas the boiler tube surface remains its color, the substrate material underneath will keep its own thickness.

- Monitoring the performance of a power boiler: Without an insulation solution, the system loses a significant amount of power. Boiler Tube Coating can help the system works more efficiently by enhancing thermal management and improving heat transfer for the lower FEGT ( The Furnace Exit Gas Temperature).

- Ensure environmentally safe: when the boiler system is working, it may create volatile organic compounds – VOCs (compounds that have a high vapor pressure and low water solubility). Boiler Tube Coating is the ideal solution to protect the environment and human health from VOCs.

2. Material options for Boiler Tube Coating: Removable coating and permanent coating

Boiler Tube Coating for each structure will have its solution to ensure optimal suitability and efficiency. Superior materials can be mentioned as Fiberglass, Mineral wool, Cellulose, Natural Fiber, Polystyrene, Polyisocyanurate, Polyurethane. However, two main options when applied to structures requiring insulation are removable or permanent. Here’s some information on the functions and benefits to help you make the best choice for you.

-

Removable Boiler Tube Coating

Removable insulation is exceptionally flexible, ideal for curved or intricately shaped structures. It is also incredibly convenient in case you often need to check your system or in case of boiler tube repair needs. This coating is quick and easy to install and can be removed whenever you need access to system components. All of this makes them convenient coating solutions to effectively reduce heat and energy loss without the need for permanent mounting.An excellent example of this type of material is insulation blankets. Blanket buckles can be made from various materials such as velcro, straps, springs, snaps. The design ensures easy on and off but is still firm. The insulation blanket is also known as the leading solution for Boiler Tube Coating.

-

Permanent insulation coating

This is a standard solution in cases where access to the system is not necessary or frequent. This material has strong properties, permanently enclosing the structure to be insulated. Permanent insulation is ideal for small spaces that need long-term insulation and does not require frequent inspection and access.

3. Factors affecting the choice of boiler tube repair material

Boiler Tube Coating entails more than just choosing the suitable application form and materials. Many contributing elements must be considered to have durable, effective, and safe insulation, including:

- You or plant personnel can perform minor pipe insulation jobs. But for large pipelines, you should hire an experienced contractor to take care of the works

- Boiler tube repair and insulation is a long-term and worthwhile investment. So don’t use old or cheap materials. Buying good quality materials is essential – this small additional cost will yield a more considerable benefit

- Compare and evaluate the maximum temperature reached by the insulation material with the system’s operating temperature

- Indoor and outdoor components will have different insulation requirements requiring expert judgment

- The ambient temperature where the insulated structure operates

- Desired “induction temperature” of the outer surface when the component is covered with insulation

- Factory specific safety requirements

- Consider space limitations and difficulties (if any) when approaching the system for an effective treatment plan

- System aesthetic requirements after boiler tube coating installation

- For certain materials, expansion and contraction should be considered under the environmental conditions in which it operates to make suitable installations

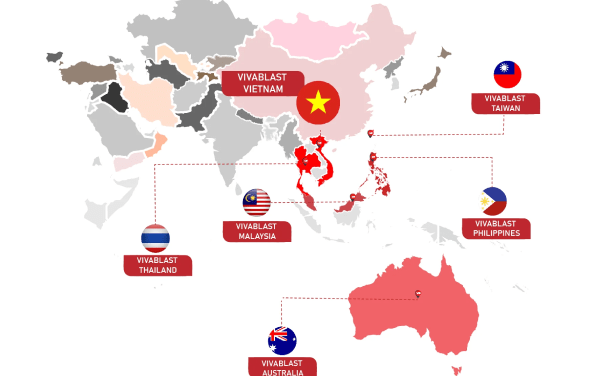

With the increasing frequency of operations, Boiler Tube Coating in factories is no longer a solution but a must. When the system is effectively insulated, the cost and performance benefits will far outweigh your initial outlay. Moreover, a safe, healthy working environment is essential for your workers to work hard, significantly improving their performance.Choosing a professional and reputable service provider and solution consultant is an essential first step for your system to have the most optimal insulation solution. At VIVABLAST, we offer a full range of insulation materials with advanced construction methods. Our team of experienced technicians will thoroughly evaluate your system and offer the most effective – economical – safe Boiler Tube Coating solution for you.

With the increasing frequency of operations, Boiler Tube Coating in factories is no longer a solution but a must. When the system is effectively insulated, the cost and performance benefits will far outweigh your initial outlay. Moreover, a safe, healthy working environment is essential for your workers to work hard, significantly improving their performance.Choosing a professional and reputable service provider and solution consultant is an essential first step for your system to have the most optimal insulation solution. At VIVABLAST, we offer a full range of insulation materials with advanced construction methods. Our team of experienced technicians will thoroughly evaluate your system and offer the most effective – economical – safe Boiler Tube Coating solution for you.