Blade repair a part of GWO training – a necessary course for those who work in the wind turbine industry. Have you ever heard about this course and why it is considered as a crucial factor to help wind turbine engineers perform their works successfully?

The meaning of blade repair and why all wind turbine experts should acquire blade training

Before taking blade repair training, participants need to know the meaning of this program, including the curriculum, the content, and how to register.

What is blade repair course? Why does blade repair course have an important role in the wind turbine industry?

The Blade Repair course is a GWO-required course for wind industry employees, particularly those who work in the inspection and maintenance fields. The certifications, including the knowledge, abilities, and attitudes required to work safely in blade maintenance, have been acquired, as well as that the safety precautions employed have been met in accordance with the identified risks.

The training will primarily focus on recognizing, managing, and reducing the hazards associated with blade inspection and maintenance works. This is an introductory course that does not require any prior knowledge of blade maintenance.The GWO blade training module will also provide trainees with the information, skills, and confidence to properly respond in a dangerous scenario and to increase their performance by using suitable equipment, safety devices, procedures, and safe craftsmanship.To learn more about GWO training, especially the first GWO center in Vietnam, you can take a look at “With GWO training, the road to becoming a good wind turbine engineer gets closer.” post.

Which requirements need participants to meet to master blade repair skills proficiently and perfectly?

Anyone taking part in the blade repair course must be in good health and able to participate fully. In particular, engineers must be informed of the dangers and hazards of completing this course when allergic to the materials used in the module. This also applies to attendees with asthma and “hyperhidrosis manuum”, generally known as excessive sweating in the hands.Due to the intensive nature of the training, participants will be required to sign a statement stating that they are medically fit to participate in the training course and that they do not have any medical conditions that would prevent them from fully participating in the training course or expose them to hazard or risk, or that they are not under the influence of any impending substances such as narcotics or alcohol.

After completing the GWO blade repair training course, learners will be able to perform and document a wind turbine blade inspection, as well as perform repair work in accordance with a work instruction while maintaining the aerodynamic profile and structural integrity of glass fiber reinforced composite parts of a wind turbine within the following dimensions:

- Trailing edge repairs up to 1,5 m in length

- Leading-edge repairs up to 1,5 m in length

- Laminate repairs down to core material

- Core material replacement up to 200 cm²

- Surface repair to paint and gel coat

The training course is for beginners; therefore, attendees will not be asked to repair important structural elements of blades such as spars, spar caps, or carbon fiber.

Why do wind turbine technicians need blade repair training for their professional development?

With all the given information above, blade training should be an ideal course for people working in the wind industry to help them gain more valuable experience and knowledge for their careers.

The course features six main points, which are listed below:

- An overview of repairing

- Personal protective equipment (PPE): what it is and how to utilize it

- Each material, chemical, tool, and other substance involved in blade maintenance is understood.

- Demonstrating your repair skills, such as fundamental lamination and repair, sandwich panel and repair, blade painting, blade inspection, lightning protection systems, and inspection, grinding, sanding, filling, surface repairs, trailing edge repairs, and bond line repairs.

- Summary of the preceding sections

- Evaluation

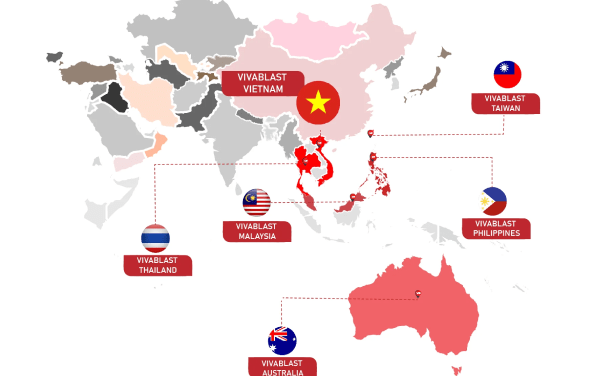

If you are a technician and want to improve your expertise, or are simply in need of more knowledge about blade repair, we hope this article is useful.In fact, this is a dangerous and technically demanding job. Therefore, repair engineers need to be well-trained in expertise, skills, and safety standards to be able to perform this job. At VIVABLAST, we have a team of highly-skilled, fully-certified technicians who conduct a wide range of wind turbine blade repair – from basic issues to full structural ones and everything in between. This also includes fixing damage caused by leading-edge erosion, which can reduce the aerodynamic efficiency of turbine blades and affect the annual energy production. With a clear understanding, VIVABLAST and our professionals have given the blade/tower its original shape and properties. Contact us today:

- Tel: (+84-28)38 965 006/7/8

- Fax: (+84-28)38 965 004

- Email: vivablast@vivablast.com