Scaffolding is a part of essential equipment in construction and maintenance. Due to its outstanding advantages, ringlock scaffolding (COBRA) has been applied in many fields of industry. This article will show you the features and exceptional features of ringlock scaffolding (COBRA).

General information of ringlock scaffolding (COBRA): comparison, structure, and advantages

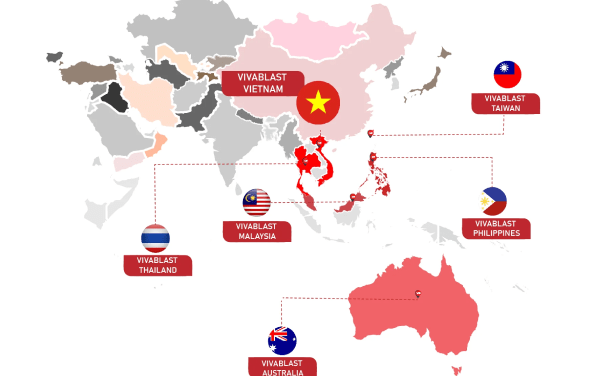

Ringlock scaffolding (COBRA) is also known as 8-hole disc scaffolding, which has been used in many countries worldwide. In recent years, this type of scaffolding has also become popular in Vietnamese construction. Here is some basic information about ringlock scaffolding (Cobra), such as structure, characteristics, and differences from conventional scaffolding.

1. Distinguish between ring scaffolding and ringlock scaffolding (COBRA)

Ring scaffolding is also known as 4-hole scaffolding. This type of scaffolding connects vertical struts and crossbars using a cast wedge and wedge pocket system. Meanwhile, ringlock scaffolding (COBRA) is an 8-hole disc scaffold, and the barriers are connected by solid ringlock rings. This scaffolding type is also reinforced to increase stability and improve safety by cross braces. Because of its outstanding stability and solidity, the ringlock scaffolding (COBRA) is used as the floor support and cover system. Regarding ring scaffolding, the strength is not as high as ringlock scaffolding (COBRA). Therefore, the ring scaffolding is applied in small and medium-sized projects.Thanks to its outstanding features, ringlock scaffolding (COBRA) has a higher cost. Therefore, depending on each project’s requirements, the user will choose the appropriate structure. Nowadays, ringlock scaffolding (COBRA) is widely applied because of its good vibration resistance and easier installation.

Because of its outstanding stability and solidity, the ringlock scaffolding (COBRA) is used as the floor support and cover system. Regarding ring scaffolding, the strength is not as high as ringlock scaffolding (COBRA). Therefore, the ring scaffolding is applied in small and medium-sized projects.Thanks to its outstanding features, ringlock scaffolding (COBRA) has a higher cost. Therefore, depending on each project’s requirements, the user will choose the appropriate structure. Nowadays, ringlock scaffolding (COBRA) is widely applied because of its good vibration resistance and easier installation.

2. The application of ringlock scaffolding (COBRA) in modern industry

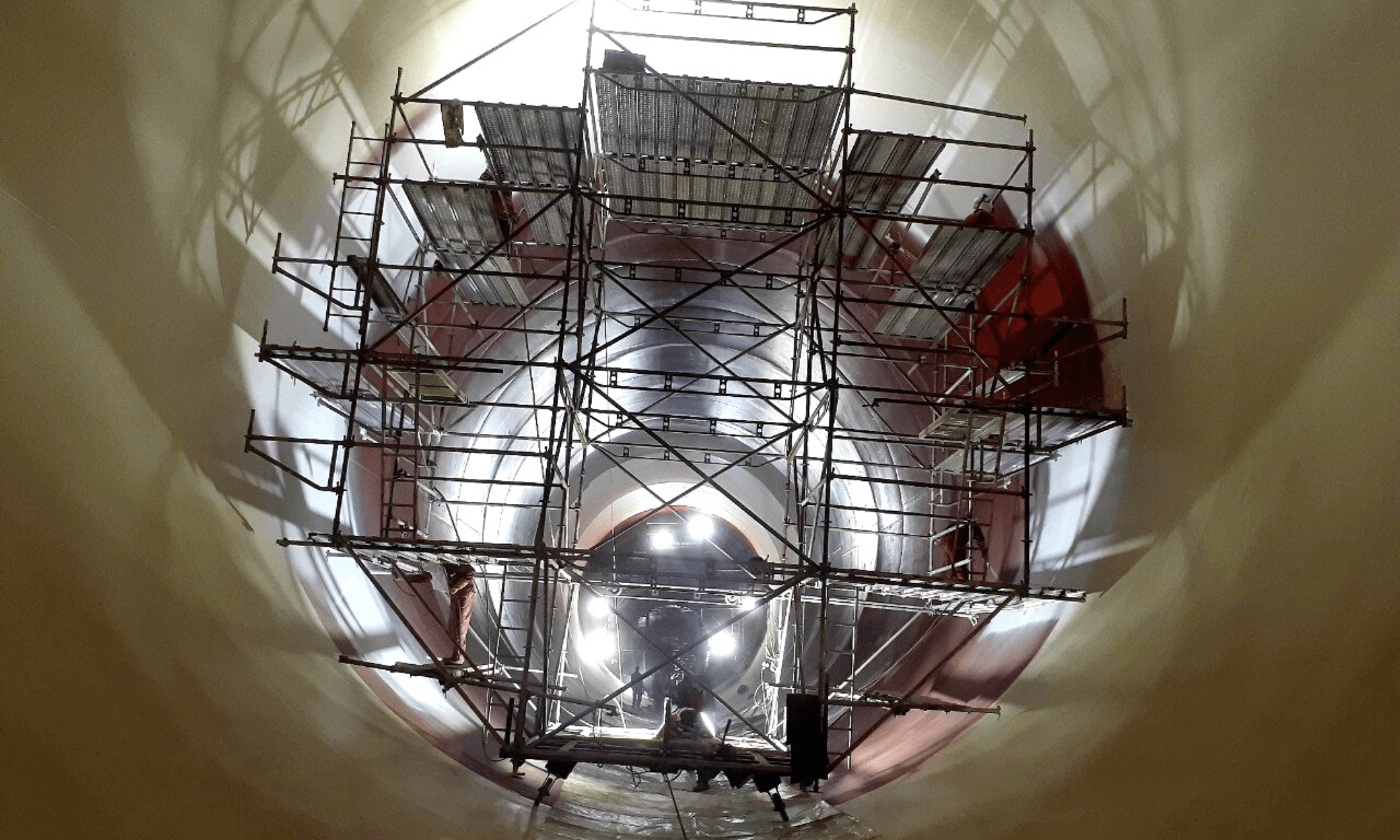

Scaffolding is used to create a height parallel to the building during construction. The stable scaffolding structure creates favorable conditions for workers to quickly move and easily carry construction materials. With good bearing capacity, ringlock scaffolding (COBRA) is often used to make floor support systems and vertical struts.In addition, this type of scaffolding is installed to form a stable frame and has a suitable height to access the wind turbine. Access with ringlock scaffolding (COBRA) for turbine cleaning and insulation installation becomes more manageable. On the other hand, ringlock scaffolding (COBRA) has high flexibility, makes insulation contractors easy to install and reasonable access to factory and factory structures. This helps quickly apply coating, repair, and maintain outside and inside.

3. Advantages of using ringlock scaffolding (COBRA) system in construction

The outstanding features of ringlock scaffolding (COBRA) make this type of scaffolding be used more widely in Vietnam. Here are some particular advantages of this type of scaffolding:

- The connection position between the floor supports is firm, the scaffolding’s vertical struts have a higher bearing capacity and load.

- The strut is designed to be simple for easier erection, quickly dismantling, and transporting operations.

- The number of beam struts between the floor cells is also minimized so that the construction is fast and does not take up much space.

- Ringlock scaffolding (COBRA) also has high flexibility, connecting with scaffolding poles at many angles, suitable for many sizes and uses.

- This type of equipment improves and develops wedge scaffolding, so it can overcome the disadvantages of coupling and optimal strength.

- Ringlock scaffolding (COBRA)comprises galvanized or cold-dipped galvanized, or hot-dip galvanized steel pipe. That helps the structure resist corrosive agents well, keeping the frame’s appearance intact for a long time.

You can learn more about the essential components, structure, and outstanding features of ringlock scaffolding through the article “Ringlock scaffolding overview – a safe and cost-effective solution”

Simple and accurate ringlock scaffolding (COBRA) installation process

The process of installing a ringlock scaffolding (COBRA) system will take place in the sequence of 4 steps below. Each step requires proper technique to ensure stability and safety:

The process of installing a ringlock scaffolding (COBRA) system will take place in the sequence of 4 steps below. Each step requires proper technique to ensure stability and safety:

1. Prepare the area where ringlock scaffolding (COBRA) will be installed

The ringlock scaffolding (COBRA) installation surface needs to ensure flatness, no slopes, and distance from power lines. Before installation, it is necessary to conduct leveling to ensure safety by pouring concrete or cement on the surface. However, it is possible to customize the surface treatment accordingly depending on the terrain.

2. Arrangement of jack footpads and locating ringlock scaffolding (COBRA) jack legs

The positioning of the scaffolding jack foot plays an important role before proceeding with this operation. You need to install additional pads underneath to avoid settlement of the foundation, ensuring the life of the worker. The ringlock scaffolding jack base has a minimum length to accommodate 2 supports. After installing the pads, you proceed to install the jack feet so that the distance between the supports should not exceed 2m (or 1.3m if this is a small scaffolding system).

3. Installation of ringlock scaffolding (COBRA) piers

Install and fix the ringlock scaffolding posts vertically. Then, install horizontal and vertical braces to create a floor system. Use a ruler to level the bars by regulations to ensure straightness without causing collapse and shaking. According to rules, the number of struts and braces must be guaranteed, not omitted if unnecessary and lacking professional calculations. Then, you use a hammer to firmly fix the joints.

4. Install cross brace and floor plate

After fixing the coupling with a hammer, install the cross braces according to the approved design. The next step, install the sheets to carry out the erection of more ringlock scaffolding (COBRA) floors at higher positions. You can install more scaffolding ladders, console ringlock, and anti-skid ringlock scaffolding if necessary.VIVABLAST provides a ringlock scaffolding (COBRA) system with prestigious international standards and quality. VIVABLAST’s scaffolding system will help you access the site to complete maintenance and construction more safely.In general, ringlock scaffolding (COBRA) possesses many outstanding features, suitable for applications in many modern constructions. For more specific advice about VIVABLAST’s ringlock scaffolding system, please contact us through:

- Tel: (+ 84-28) 38 965 006/7/8

- Fax: (+ 84-28) 38 965 004

- Email: vivablast@vivablast.com

Trusted industrial rope access from VIVABLAST – One of the world’s leading providers