Dedusting systems play a vital role in various industries, from manufacturing and mining to construction, ensuring a safe and healthy working environment. However, designing and operating these systems can present significant challenges. Issues such as excessive pressure drop, blockages, noise, and vibration can impact system efficiency, increase maintenance costs, and even pose safety hazards. To address these challenges, innovative solutions are needed, and 3D modeling has emerged as a powerful tool in optimizing dedusting system design and performance.

The Role of 3D Modeling in Addressing Dedusting Challenges

3D modeling provides a virtual environment for engineers and designers to analyze and optimize dedusting systems before physical construction. This allows for:

- Identifying and mitigating pressure drop issues: By simulating airflow through the system, 3D models can pinpoint areas of high pressure drop, enabling designers to optimize ductwork dimensions, improve airflow, and minimize energy consumption.

- Optimizing airflow and minimizing turbulence: 3D modeling can help visualize airflow patterns, identify areas of recirculation or stagnation, and optimize ductwork configurations to minimize turbulence and ensure efficient dust removal.

- Predicting and preventing blockages: By simulating the movement of dust particles within the system, 3D models can identify potential blockages and optimize ductwork geometry to prevent dust accumulation.

- Reducing noise and vibration levels: 3D modeling can be used to analyze noise propagation and vibration transmission within the system, allowing for the identification and mitigation of noise sources and vibration points.

- Improving system efficiency and energy consumption: By optimizing system design and minimizing pressure drop, 3D modeling can significantly improve the overall energy efficiency of the dedusting system.

3D Modeling Techniques for Analyzing and Optimizing Dedusting Systems

Several 3D modeling techniques can be employed to analyze and optimize dedusting systems:

- Computational Fluid Dynamics (CFD): CFD simulations can accurately model airflow patterns, pressure distribution, and dust particle trajectories within the system. This allows engineers to evaluate different design options and optimize ductwork geometry for optimal performance.

- Finite Element Analysis (FEA): FEA can be used to assess the structural integrity of ductwork components, identify areas of high stress, and optimize the design to prevent failures.

- Acoustic Simulations: Acoustic simulations can predict noise levels generated by the dedusting system, allowing for the identification and mitigation of noise sources.

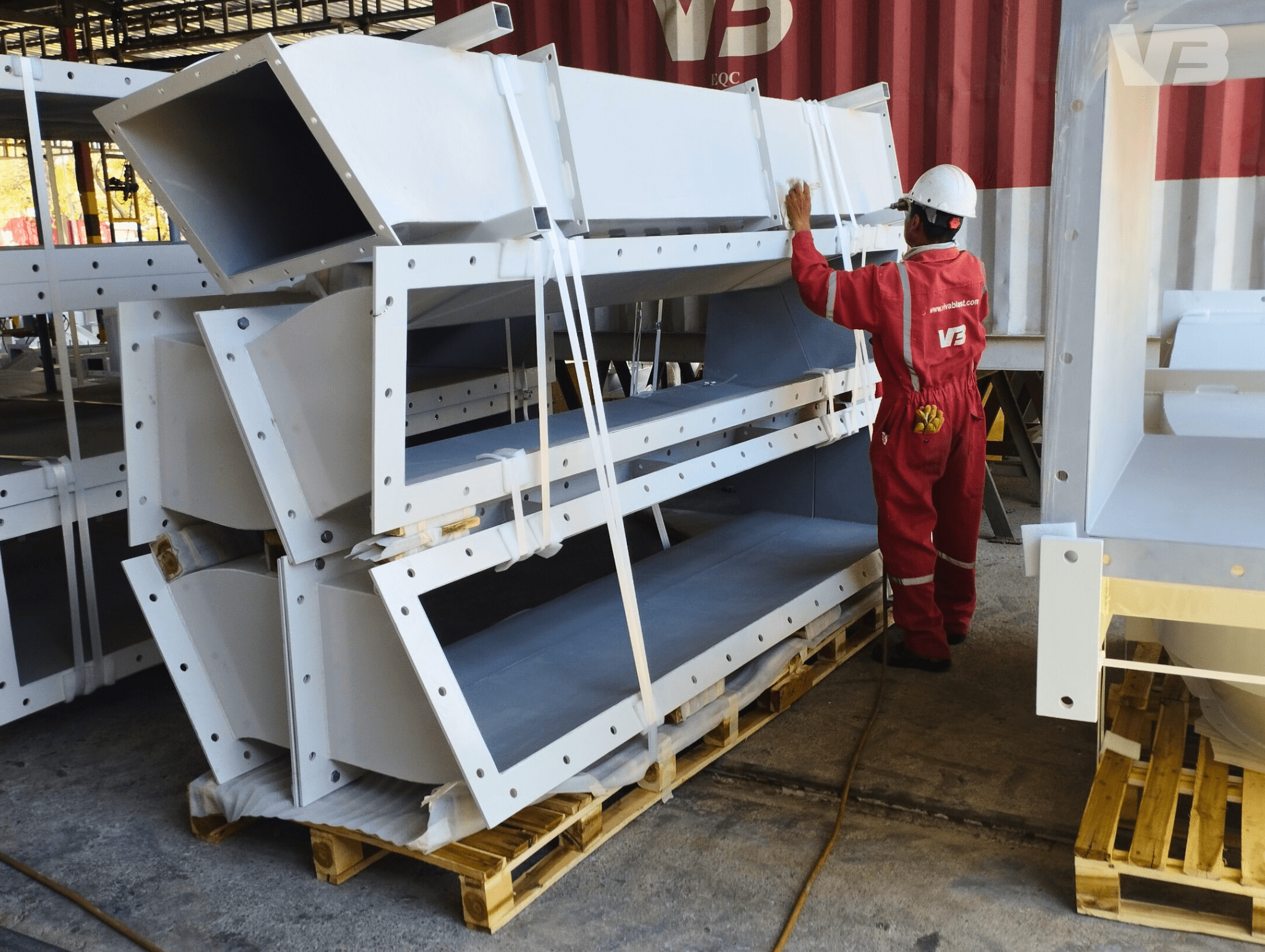

Case Study: A Real-World Application

Future Trends and Considerations

The future of dedusting system design lies in the continued development and integration of advanced technologies:

- Integration of real-time data and sensor feedback: Real-time data from sensors within the dedusting system can be integrated with 3D models to provide dynamic insights into system performance and enable real-time adjustments.

- Development of advanced simulation tools and software: Continued advancements in simulation software will enable more accurate and detailed modeling of complex dedusting systems.

- The role of 3D modeling in the design of smart and sustainable dedusting systems: 3D modeling can play a crucial role in the development of smart and sustainable dedusting systems that are energy-efficient, environmentally friendly, and adaptable to changing operational needs.

Conclusion

3D modeling is a powerful tool for addressing the challenges associated with dedusting system design and operation. By leveraging the capabilities of 3D modeling techniques, engineers can optimize system performance, reduce costs, and improve overall efficiency. As technology continues to advance, we can expect even more innovative and sophisticated solutions for designing and operating sustainable dedusting systems.