What are mechanical contractors and their scope of work? How can we evaluate and select an experienced contractor? What mechanical solutions does VIVABLAST provide? All will be presented in the article below.

Mechanical contractor: General information should not be ignored

The article includes three main ideas:

- A brief introduction to the mechanical contractor

- 3 criterias to choose a high-quality and suitable mechanical contractor

- High-quality mechanical solutions provided by VIVABLAST

Mechanical contractors: Who are they and what are their responsibilities?

Mechanical contractors are those responsible for overseeing mechanical projects. They are in charge of the building’s heating, cooling and plumbing systems. Some other contractors also manage maintenance and repair for buildings throughout their lifespan. To better understand the scope of work of these contractors, let’s take a look at some typical mechanical items in a building or structure:

- HVAC system: Heating, ventilating, air-conditioning equipment.

- Cooling system: artificial cooling by transferring heat around or moving heat from one area to another.

- Plumbing: Pipes, tanks, fittings… control the process of water supply, heating, and sanitation.

- Power system: The electricity supply network, distribution, and use, including overhead and underground lines, power poles, transformers…

The responsibilities of a mechanical contractor vary from project to project, but they typically perform the following tasks:

The responsibilities of a mechanical contractor vary from project to project, but they typically perform the following tasks:

- Project human resource management

- Task assignment to team members

- Design mechanical parts, then perform the on-site installation using VDC/BIM solutions

- Monitor construction resources such as equipment, materials…

- Supervision of electrical construction and maintenance scope

In a large project, mechanical contractors will coordinate with many contractors in charge of other jobs to accomplish a final goal. They must also ensure that the work is completed within the deadline and budget specified in the contract.

3 criteria to choose a high-quality and suitable mechanical contractor for your project

1. Licensing and InsuranceYou need to find a qualified mechanical contractor, especially when working with an HVAC system, as it can be costly. A trustworthy company should have a full license and corresponding insurance, and this information is usually published on the contractor’s website. If not, you need to ask them to show it to you when discussing it in person.2. Online reviews from their previous clientsThe Internet is a great resource whenever you need to find information and quality reviews of contractors. However, consult selectively and multi-dimensionally; Pay special attention to the comments of customers who have many similarities with you (about the project, budget, time, type of work…)3. Financing or leasing offersAs mentioned above, mechanical items and parts like HVAC are often costly. Therefore, you can prioritize mechanical contractors who can offer reasonable prices, financial support, or mechanical leasing policies. Thus, you can reduce the financial burden on your projects, especially large-scale projects.

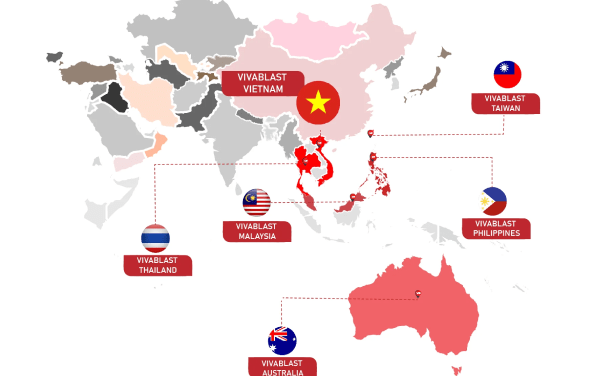

VIVABLAST – A leading mechanical contractor with a wide range of services

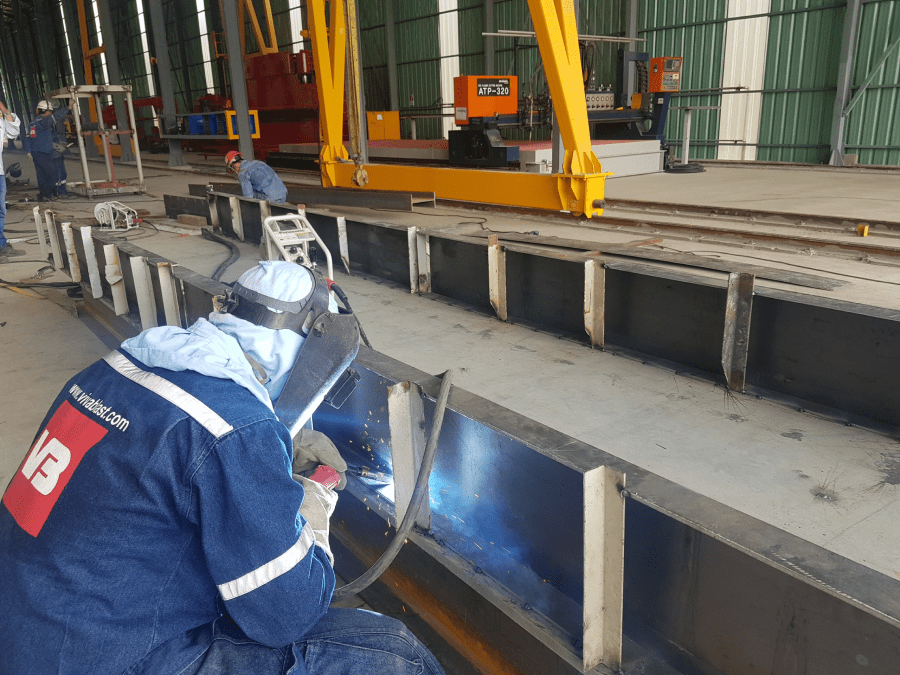

VIVABLAST is an experienced mechanical contractor, currently providing five separate groups of mechanical services; each group includes many minor work items. Details are as follow:

1. Equipment mechanical maintenance

| SERVICE | DESCRIPTION |

| Expansion joint replacement | New expansion joint supply and installation to protect the pipeline in the thermal expansion process |

| Filter house repair | Louver and Roof fabrication, Steel structure replacement, Scaffolding, and Painting application |

| Plant refurbishment | Scaffolding, Steel structure replacement & Anti-Corrosion painting application |

| Diffuser repair | Support change, new bolt & nut installation, internal & external repainting, and insulation |

| Boiler fin tube repair | Cutting, welding, process hydraulic test to recognize leakage/abnormal deformation |

| Technical advice and upgrade | Boiler cyclones modification, and hanger inspection and replacement for the cold and hot position |

| Auxiliary boiler repair | Tank, pipeline, valve & steel structure replacement, hot works and insulation installation, re-coating. |

| Cathode protection | Welding, drilling, fitting and installing on cooling water pipeline to protect metal surfaces from corrosion |

| Wear-pad application | Surface preparation, wear-pad application at pipe support and coating for anti-corrosion protection |

2. In-situ machining and controlled bolting services

| SERVICE | DESCRIPTION |

| Cold pipe cutting and bevelling | Supply machines to part off heavy wall wipe and perform bevels for various weld preparations due to its precision and higher safety |

| Flange facing | Provide flange facing solutions from 2” diameter up to 126” diameter on any material to meet the surface finish as required. |

| Controlled bolting | Provide technicians and equipment to ensure leak-free bolting connections properly on any bolted joints safely and competently |

3. Boiler and turbine cleaning services

| SERVICE | DESCRIPTION |

| Chemical cleaning | Apply chemicals for cleaning and supply QA/QC supervisors to check and record result |

| ALU OX abrasive cleaning | Use particles to blast and clean the surface applied for gas and steam turbine |

| Coal-fired boiler cleaning | Remove coal slag and refractory by using rope access as the main access method |

4. Thermal spray service

| SERVICE | DESCRIPTION |

| Innovative repair methods | Apply thermal spray with high quality and long term guarantee, use of different materials applied to specific equipment/ metal parts such as Aluminum, Zinc, Alloy (HVOF) for prevention of metal loss and protection of structure in long-term operation:

|

5. Commissioning and pre-commissioning

- Startup seawater system, closed cooling water, chemical

- system

- Lube oil, hydraulic oil…

- Run test for the pump, air compressor, fan

- Correct flow rate, pressure, temperature value for operation

- Short circuit test, earth test, synchronizing, energization load test, load reject test

So why is VIVABLAST a reliable mechanical contractor?First, we have a full range of mechanical installation procedures, ensuring accuracy and being on schedule. All machines are installed by a qualified professional team with a sense of responsibility, who possess certain qualifications from International Organizations, based on International Standards such as ASME IX, ISO 9606… We apply international standards (the latest ISO 45001: 2008 and OHSAS 18001) to all of our mechanical solutions. VIVABLAST owns a team of technicians with many years of experience working for large-scale production workshops.In addition, we also have many outstanding advantages such as:

- Competitive service cost

- Excellent warranty and maintenance service

- The construction process is fast, ensuring on-time as given by the client.

In general, mechanical – insulation contractor effectively support all projects, from the construction phase to maintenance and repair. A reputable contractor needs to be fully certified and insured, have standard processes, a professional team, and modern machines. They also need to meet the budget and time requirements of the project. And with nearly three decades of experience, VIVABLAST confidently meets all of the requirements above. Contact us today for detailed consultant:

- Phone: (+ 84-28) 38 965 006/7/8

- Fax: (+ 84-28) 38 965 004

- Email: vivablast@vivablast.com